An electrifying idea

Induction technology has already found its way into small appliances, but it also promises exciting possibilities for warehouse technology and trucks.

2017-10-18

Induction technology has already found its way into small appliances, but it also promises exciting possibilities for warehouse technology and trucks.

2017-10-18

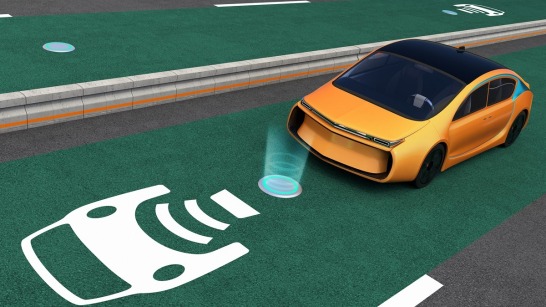

A forklift truck that can recharge itself via a plate in the floor, rather than having to return to a power outlet, is the current vision for inductive charging. And this is by no means science fiction. In some Italian cities, electric buses that recharge their batteries at bus stops have been in use since 2002, and in Germany, similar pilot projects have been running since 2015. The car industry has also been working hard on making inductive charging production-ready. “However, a forklift truck is not a bus,” says Kai Haake, development project manager at STILL. A truck offers less room, requires sufficient ground clearance, and must be more robust. These are some of the unique challenges that the intralogistics sector faces on its way toward inductive battery charging.

Interest in the technology has increased since the introduction of lithium-ion batteries, as they also allow intermediate charging and cannot just be charged when they are running low. This is more efficient in day-to-day production and warehouse operations where there are regular short periods when a truck is not in use. “Three minutes is generally not enough to drive the truck to the central charging point,” says Haake. However, the ability to recharge via induction at a number of waiting points would be very useful. It would mean the fleet could be deployed faster and with greater flexibility, and it would require less maintenance as there would be no risk of wear and tear to power cables and connectors. “It would be a very convenient system,” says Haake.

“We have been monitoring this trend for some time”

That is certainly the aim of using induction technology, and one of its most promising areas of application. It is difficult to calculate precise costs at the moment, as the sector is still conducting research and working on finding the best system – as are the brand companies of the KION Group. “It’s hard to overestimate the long-term benefits,” says Joachim Tödter, head of technology and innovation at the KION Group. “We have been monitoring this trend for some time.” Warehouses have many unique features that must be considered, and these mainly relate to how a truck is built and how induction works.

Two magnetic coils generate an alternating electromagnetic field, and thus an induced voltage, when they are placed as close as possible on top of each other. Electric toothbrushes and small electrical appliances can already be conveniently charged this way. To ensure that charging runs smoothly, there cannot be any iron between the coils, as this would get too hot. The coil’s housing must be made of a non-conductive material, such as plastic, and be attached directly to the underbody. But a truck usually has very little ground clearance. “If you add another plate to the underbody, the truck may no longer be able to get up steep ramps,” says Haake. “Our trucks are already full of technology, often leaving very little room for anything else.” Buses do not have this problem, so the engineers need to find a new solution here. The same applies to the charging plate – it cannot be reinforced with metal, but needs to be sufficiently robust to withstand heavy warehouse traffic, water jets, oils, solvents, and any number of other chemicals that might be used in a lot of companies’ processes. “It would be extremely inefficient to have to develop a charging plate for each environment,” Haake adds.

Exciting challenges that are within the realms of possibility

“We will need an innovative housing solution and a tough plastic, probably fiber-reinforced,” Haake summarizes. He believes that engineers will be excited about these challenges, such as developing a counterbalance truck with a lithium-ion battery that works with induction technology. Counterbalance trucks usually have an internal combustion engine, as they require a lot of energy and high performance. Haake does not see a contradiction in this: “The ability to charge lithium-ion batteries at regular intervals could help them to achieve the same level of performance.” But counterbalance trucks are also workhorses that have to be particularly robust in day-to-day operations. Which is why the demands made of materials used in induction technology are so high, and why placement is so crucial. With smaller warehouse trucks, the induction unit could probably be attached to the front or the side. These are creative challenges, but nothing that would currently appear insurmountable.

As with so many other future technologies, a lot will depend on how soon customers are ready to invest in it. And also on how the development of inductive charging for other vehicles progresses. “It’s entirely possible that we will see generic charging points where forklift trucks, goods vehicles, and company cars can be charged,” Haake says. This throws up the question of compatibility between the technologies developed by the various manufacturers and sectors. In principle, this should not be a problem, “but nobody really knows what everyone else is planning.” And at the moment, nobody is keen on sharing information with anyone else. The KION Group is certainly prepared for all eventualities: Over the coming years, the company will continue to increase the number of models featuring lithium-ion batteries, and it will keep on monitoring developments in induction technology. Its objective is not to create a range of special models; KION wants to produce a fleet of innovative, high-performance warehouse trucks that feature induction technology and can be deployed flexibly.