Abassin Aryobsei, Vice President for Product Strategy & New Technologies at KION Group AG, also sees a great deal of potential for artificial intelligence in intralogistics, primarily in vehicles, but also in terms of overarching control: “AI will allow us to continuously optimize systems. The systems will be able to learn, and they will continuously share the intelligence they have acquired with other systems. We can really expect a lot from the future,” he predicts.

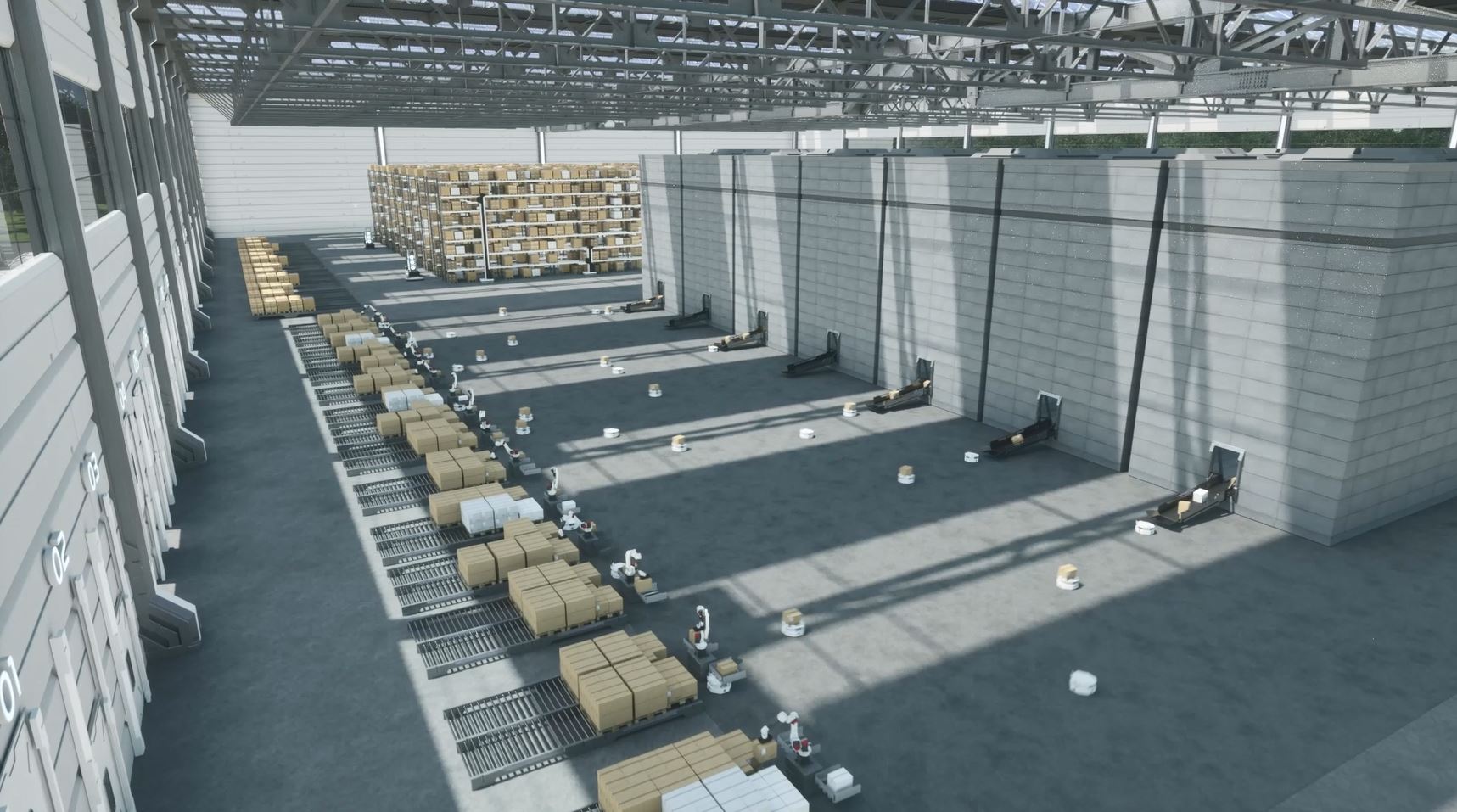

Dynamic Swarms Instead of Rigid Systems

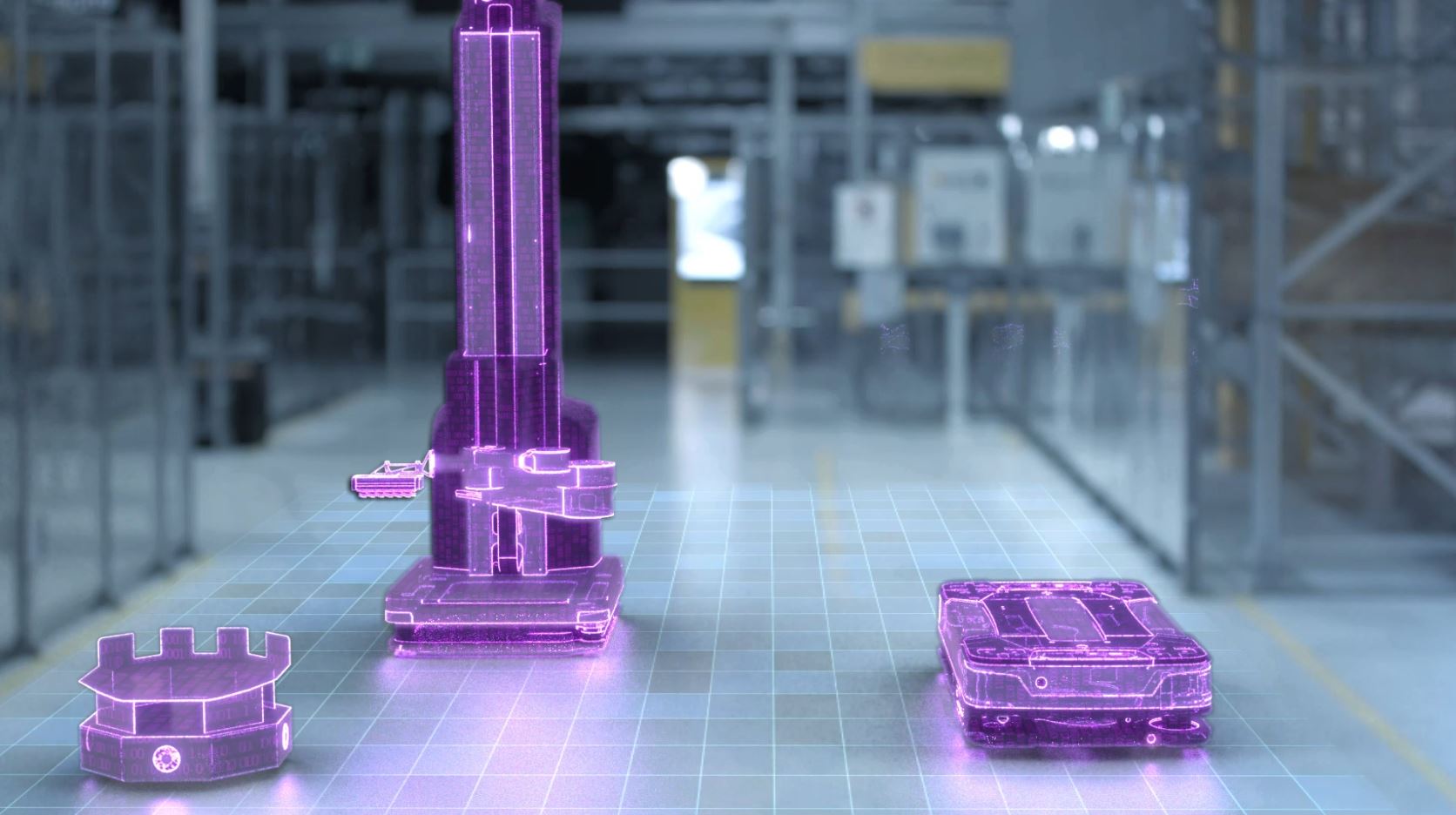

In the long term, smaller transport systems like the LoadRunner, or AMRs (autonomous mobile robots) like the C-MATIC from KION daughter company Linde Material Handling will replace fixed material handling systems. The latter are still a common sight in many warehouses and distribution centers. Implementing these systems requires long-term planning: Once they have been built, the layout is relatively set in stone. The future will look quite different with the introduction of transport robots, as they can be deployed anywhere and routes can be flexibly adjusted at any time. As a result, they will offer a new, unfathomable degree of freedom when it comes to designing warehouses in future.

Another benefit of the LoadRunner swarms and AMRs is that when one device fails, another transport robot will simply take over the job it was doing. Unlike in the case of automated conveyors, one technical problem no longer causes the entire system to come to a standstill. The flexibility and almost limitless scalability of these new systems will allow warehouses of the future to achieve a greater degree of reliability as well as optimal, needs-oriented capacity utilization thanks to smart coordination of all processes.