In the last 100 years, supply lines, customer expectations and the shopping experience have undergone considerable changes. Small local stores with a limited range of mostly regional produce have been overtaken by huge supermarkets with an almost unlimited selection of fresh produce from around the world. E-commerce now drives the next phase in this evolution, allowing for fresh produce to be ordered online for fast home delivery.

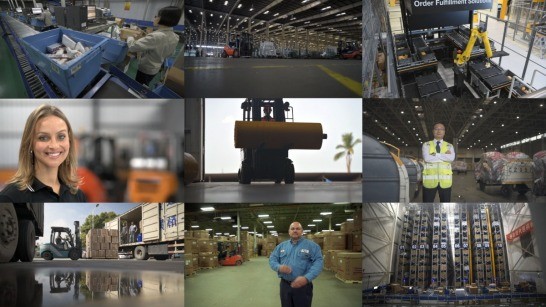

The transition over the last few decades from a small range of regional produce to the unlimited international selection on supermarket shelves today is primarily due to groundbreaking technological developments and automation solutions. Some of these have either been developed or refined by KION Group’s brand companies. Since the industrialization of the grocery food industry, numerous innovations in storing and transporting food have created the space for new products and enabled an ever-increasing, global exchange of goods. Whether it was the first automated guided vehicles (AGVs) in the 1950s, the systems developed by industrial crane producer Demag in 1975, which Dematic previously was a part of, or today’s robot pickers, they have all heavily played a role in shaping the current grocery food market.

The industry continues to evolve, with a growing number of customers now shopping online. Just a few hours after placing their order, customers can collect their items at the nearest supermarket or have it delivered directly to their homes. However, increasingly complex logistics facilities are needed to provide this type of food shopping experience efficiently and rapidly.

Flexible logistics required

Well-planned warehouses, intelligent fleet management and robust hardware are key to meeting today’s expectations. Temperature zones are particularly crucial within the grocery food industry. In the refrigerated warehouse of Dutch fish retailer Schmidt Zeevis, a STILL very narrow aisle truck optimizes processes at up to minus 30° Celsius. The company also operates an online shop, so the truck needs to be reliable and fast – even at very low temperatures. The latest electric industrial trucks with optimized charging are ideal for keeping refrigeration chains going, even during tough, multi-shift operation. This allows freshly harvested produce to make its way onto the shelves even faster.

Trucks made by KION’s assorted brands are just as reliable working in the hot sun as they are in a frosty refrigerated warehouse. Up to 12,000 packages leave California-based vegetable grower Ratto Bros. every day. The vegetables are harvested in the morning and then chilled, packaged and delivered to supermarkets. Speed and reliable equipment are vital to securing the complex supply chain for these perishable goods, which is why the company has been operating a fleet of cutting-edge electric forklift trucks from Linde MH for some time.

Automation provides a competitive edge

When it comes to picking orders, a very high throughput rate is key. Australian food retailer Drakes Supermarkets achieves this at its distribution center with Dematic’s robotic piece picking module. Micro-fulfillment facilities are also springing up in urban centers. These small, fully automated warehouse systems, located at the back of local supermarkets, can pick online orders autonomously and are particularly suited for the fast delivery of food items. Automation can provide the decisive competitive edge in the daily battle for satisfied customers.