That is indeed a very bold prediction. But you must surely be aware that there are still strong reservations about Chinese industrial truck manufacturers, especially in Germany and the rest of Europe?

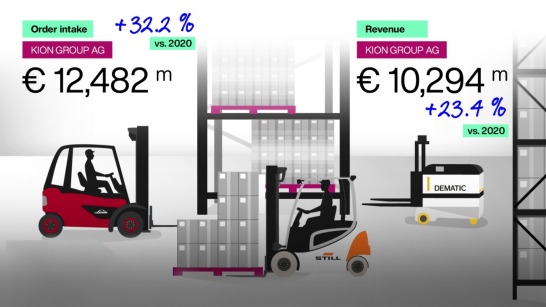

Bischof (now extremely serious): Of course, I am aware of this bias—even if it isn’t always justified. In our case, however, the situation is completely different from that of our Chinese competitors. Although the forklift brand BAOLI was founded in China in 2003, it was taken over by the global intralogistics group, KION Group, in 2009—the second largest manufacturer of industrial trucks in the world. Membership of the Group comes with copious mutual benefits and strengthens our brand immensely, especially as KION GROUP AG is based in Frankfurt, which is in Germany. We offer European quality standards for our products, but we use our Chinese manufacturing expertise—which is cheaper than in Europe. In other words: We combine European development DNA with cost-efficient Chinese production methods. This results in high-quality and very competitive products which are unrivaled by the rest of the industrial truck entry-level segment on a global scale.

And how are things looking for Service? As I’m sure you know, no industrial truck user can afford to wait four weeks or more for spare parts to be delivered from China.

Bischof: This is another area in which we are fundamentally different from our competitors, as we have significantly expanded our range of after-sales solutions over the past few years. For example, we set up a central product and spare parts warehouse in Rolo, Italy. With a floorspace ofaround 14,000 square meters, the warehouse stores around 700–800 trucks ready for immediate delivery, and also has more than 11,000 square meters of space for spare parts storage. From there we can deliver almost any spare part to anywhere in Europe within 24 hours. However, there is perhaps another example that will better demonstrate our high quality requirements. While, in the best case scenario, other Chinese suppliers provide the operating instructions for their products in English, we go to great lengths to translate each manual into the respective national language. You will find these very high quality standards, shaped by the KION philosophy, in all areas of BAOLI, from development to production to customer service.

But the BAOLI machines are only ever manufactured in China, aren’t they?

Bischof: That’s right. We have our traditional production facility in the Shanghai region. At the end of December, KION opened an additional plant for the production of counterbalanced trucks in Jinan (Shandong Province), which is also where BAOLI industrial trucks are produced. Around 100 million euros are expected to be invested in this pioneering project. By 2025, the KION Group will have created more than 800 new jobs at the new site in East China. We now have an ultra-modern production facility there, which meets the very highest production standards and thus also fulfills the aforementioned quality standards.