Automation as an added feature

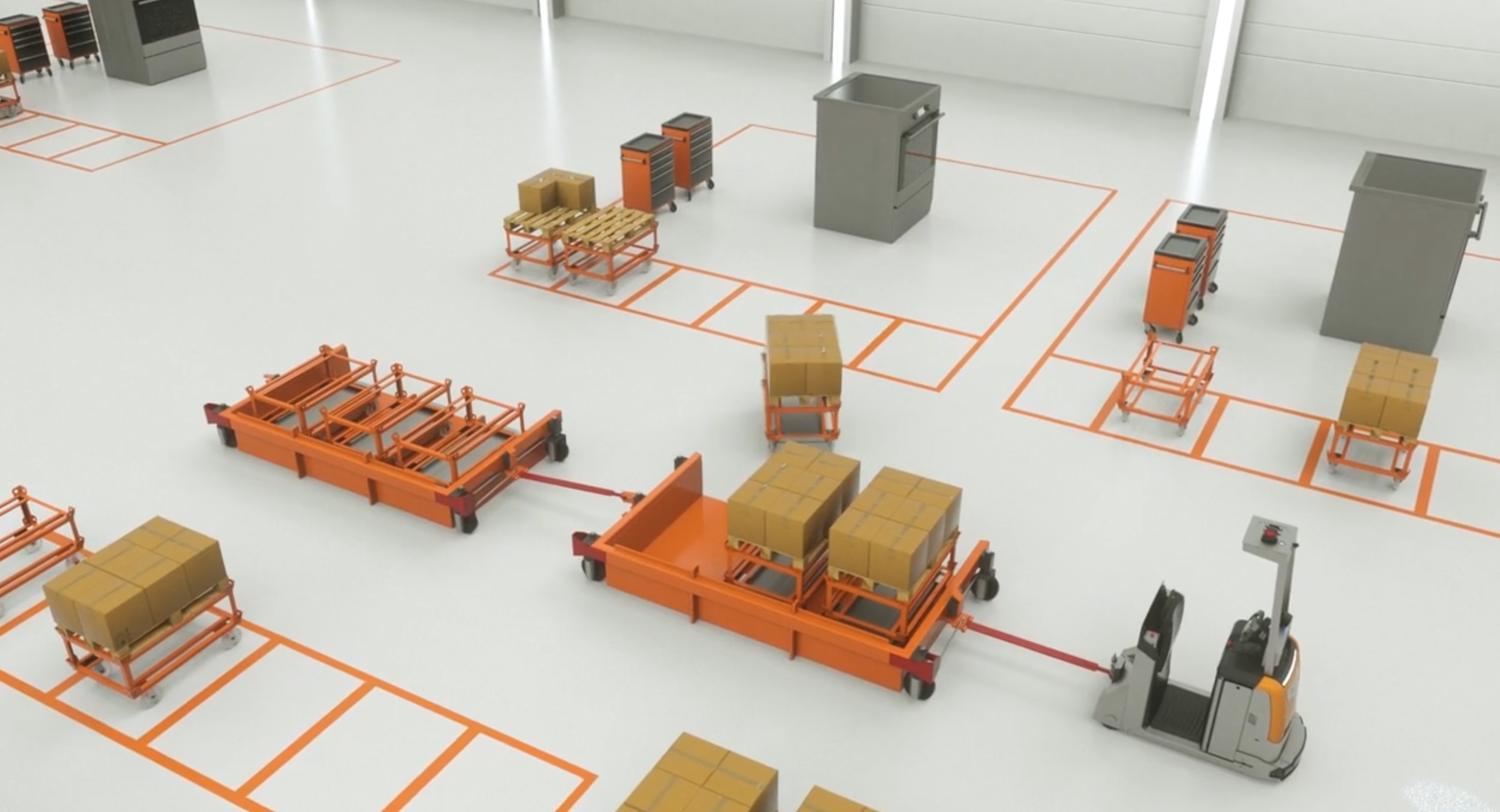

KION brand STILL has been spending a lot of time developing tugger trains and getting its own patents. Why? Because apart from the basic concept, there are several potential ways to implement the concept. "The most obvious variant is to bolt the drawbar and wheels to a load carrier," says Fischer. Yet, what at first glance appears to be efficient and simple, quickly becomes impractical when maneuvering: To gain access to the trailers, they must be uncoupled on each side every time. Additionally, these constructions are not especially nimble nor robust. It is why STILL prefers a push-in concept where loads can be pushed in and out from each side in specially manufactured, heavy-duty frames.

With a little imagination, the approach could be applied to an urban area and the last mile where a tugger train - or a tugger train-like vehicle - is utilized in densely populated areas, driving to a central location. From there, the packages are delivered to your front door. An added feature involves automating at least one of the two steps: either the tugger train, or the delivery itself. Since tugger trains only commute between the same central locations anyway, automation would be easier than it would be with a free-moving vehicle. "I can even imagine a scenario where residents know they can head to their front doors to pick up their goods when they hear a certain tone from the vehicle and then sending the tugger train back on its way by simply pushing a button," says Fischer. And perhaps before too long, you might be hearing people say, "When the tugger train honks twice". You must admit that the idea has its appeal.

Swarms of driverless transport vehicles

It is also conceivable that delivery to your front door could be automated using small driverless transport vehicles that collect packages from the tugger train and then take the shortest route from the central transshipment point to your front door. Alternatively, the destination could be a packing station or similar decentralized locations. "We're really talking about the last stretch of the route," says Fischer. "The automated vehicle could then handle a larger volume all at once like a swarm." In warehouses, this is already technically possible and STILL has developed and implemented this very solution. Fischer is convinced that the trend will pick up with customers. Driverless transport systems are one of the hot buttons in the intralogistics industry.

Noe van Bergen who is the head of Automated Solutions at STILL, is convinced the approach using driverless transport systems which control a specific destination from a central transshipment hub to be applicable to urban logistics.